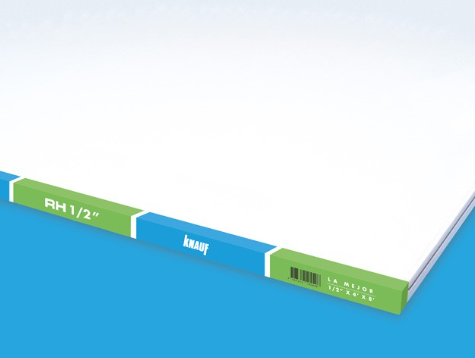

KNAUF RH – Gypsum Board / Drywall

The Knauf RH Gypsum Board consists of a natural, non-combustible gypsum core, treated to be resistant to water penetration; coated with 100% recycled reinforced cardboard with a green finish on the front, chemically treated to be resistant to moisture and mold; and a moisture and mold-resistant semi-asphalt craft color on the back. The front cardboard is folded around the longitudinal edges to reinforce and protect the core, and the transverse ends have a square, right-angle cut. The longitudinal edges are beveled to facilitate joint treatment, thereby providing a uniform finish between boards.

Basic Usage:

- The Knauf RH Gypsum Board is designed for use in wall and ceiling assemblies where moisture and mold resistance are important factors, in areas where finishes such as ceramic coverings, tiles, etc., are applied.

- Board designed to meet the needs in bathrooms, kitchens, utility rooms, etc., without being in direct contact with water.

- Fixed and suspended ceilings.

- Walls with metal structure.

- Walls with wooden structure.

MATERIAL

Sheet of hydrophobic formulated gypsum, processed between two layers of cardboard.

WATER ABSORPTION

< 5% after 2 hours of absorption.

FINISH

Smooth, clear, and suitable for receiving finishes such as paint, wallpaper, etc.

THICKNESS and NOMINAL SIZE

12.7 mm (l/2″) | 15.8 mm (5/8″) | 1220 mm x 2440 mm (4 It x 8 It)

TRANSVERSE FLEXURAL STRENGTH

12.7 mm (1/2″) Board: >476 N (107 lbf) | 15.8 mm (5/8″) Board: >654 N (147 lbf)

NOMINAL WEIGHT

24.5 kg ± 1 kg for 1/2″ board | 31 kg ± 1 kg for 5/8″ board

TYPE OF EDGES

Longitudinal: Tapered edge, type AK. Transversal: Straight edge.

DENSITY

630 – 680 kg/m3 ( l /2″) | 650- 700 kg/m3 (5/8″)

RECOMMENDATIONS

- The maximum separation between the omega profile in ceiling applications should be up to 16″ (40.6 cm).

- Any perforation made in the Knauf RH Gypsum Board in wall assemblies, to allow the passage of installations, pipes, and accessories, must be sealed with an elastic, waterproof, and non-hardening product.

- The recommended level of finish depends on the final finish:

- For rigid materials (ceramics, porcelain tiles) level 3

- For rough finish textures level 3

- For enamel paint, glossy or semi-glossy level 5

PROPERTIES

- Lightweight and economical material that easily adapts to a wide variety of decorative finishes, allowing for painting and ceramic coverings.

- Quick and clean installation.

- The Knauf RH Gypsum Board is ideal as a substrate for ceramic tiles and veneers.

- The Knauf RH Gypsum Board is easily cut and broken for quick installation. Cuts can be easily made with a disposable blade knife.

- Non-combustible.

- Can be curved (1/2″ board).

- Impregnated to reduce absorption.

- Reinforcement on the edges.

- Expansion and contraction in normal atmospheric changes are insignificant.

- Veneers should be installed with silicone-based mortar, flexible and resistant to moisture.

- The use of galvanized steel frames is recommended in the construction of walls and ceilings in humid areas.

- For sanding furniture, accessories, etc., additional elements should be placed inside the metal frame.

- The best option for walls and ceilings in semi-humid areas.