KNAUF SAFEBOARD – Gypsum Board / Drywall

What used to be a lead challenge, Safeboard now makes easy and safe. This board is fireproof, improves acoustic insulation, offers high resistance to impacts and surface damage, and above all, provides excellent protection against radiation, making it the best option for constructing an X-ray room. Knauf Safeboard partitions are metal-framed dividing walls made of galvanized steel profiles, coated with Knauf Safeboard anti-radiation plates.

At Knauf, we have succeeded in replacing the lead in medical offices and hospitals, a less eco-friendly material, with the first anti-radiation partition. 0% lead, 100% safety.

FIELD OF APPLICATION

Radiation protection plates for use in X-ray rooms in health facilities such as medical centers, hospitals, and dental centers, among others.

Knauf radiation protection systems are applicable in areas of diagnosis using X-rays and radiotherapy. The protection of this type of construction against radiation is guaranteed, considering the equivalent values in lead.

PROPERTIES:

- Economical radiation protection.

- Lead-free sheets.

- Fire protection board.

- Simple handling.

- Very good acoustic insulation.

- Easy to install

SIZE

625 mm x 2500 mm

PESO

17kg/m’

THICKNESS

12.5 mm

TYPE ACCORDING TO STANDARD

DIN EN 520 DF | DIN 18180 GKF

EDGES

Longitudinal: Wrapped in HRK cardboard and Transverse: SK.

RADIUS OF CURVATURE

Dry: r ≥ 2750 mm | Wet: r ≥ 1000 mm

RECOMMENDATIONS

- Joint filling of mixed or cut-generated joints (straight edge SK) for the most exposed layer can include beveling of edges and joint paper tape. For the process, refer to the Knauf Safeboard Technical Sheet.

NOT APPROPRIATE

- Alkaline coatings such as lime paints, soluble glass, and pure silicate; ensure rapid drying after wallpapering with paper, fiberglass wallpapers, or the application of synthetic resin or cellulose plasters, by means of adequate ventilation.

MATERIAL SPECIFICATIONS FOR RADIATION PROTECTION

X-ray examination rooms require the construction of radiation shielding to adjacent environments. The rules for the execution of radiation protection structures (active radiation and interference radiation) are established in the DIN 6812:2002 standards. The radiation protection plan should be established by the builder, according to the shielding requirement.

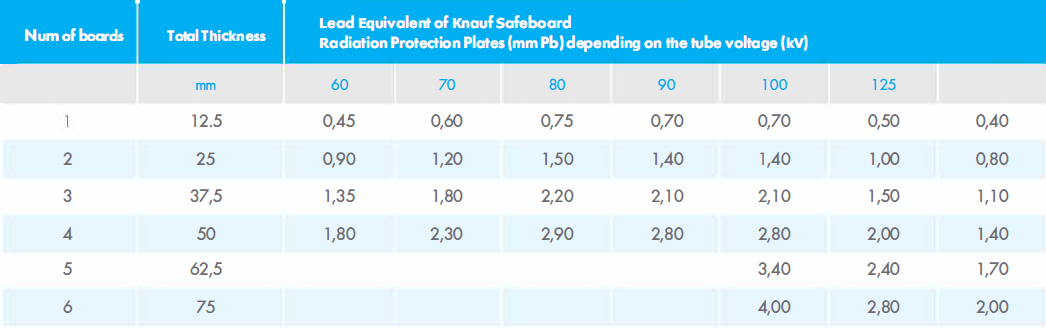

The thickness of the required protection layer depends on the voltage of the tube according to the type of installed device (dependent on the application of medical treatment) and is indicated for lead, as an insulation material. The higher the tube voltage, the thicker the lead layer needed. For protection with other materials, the protection effect is indicated as an equivalent value in lead. The equivalent lead value as a reference magnitude indicates the relationship between the material’s radiation protection effect and the equivalent lead thickness.

Table 16, according to DIN 6812 standards, includes specifications about equivalent lead values of different building materials. Heavy concrete construction elements previously installed for radiation protection in sanatoriums, hospitals, and medical offices can today be simply, rationally, and sensitively replaced by Knauf radiation protection systems.

Gypsum boards used until now with hidden lead sheets are difficult to work with due to their excessive weight and require great care in installation to achieve radiation protection without leaving escape gaps. Knauf Safeboard was developed to minimize the excess expenses necessary for the construction of radiation protection systems compared to conventional dry construction systems. This radiation protection board can be worked within the system with Safeboard putty as any normal gypsum board and offers all the technical and construction characteristics (acoustic protection, fire protection) of a conventional gypsum board. This way, fire protection requirements in radiation protection can also be met.

SAFETY INSTRUCTIONS For the installation of Knauf Safeboard, especially in sanding, saw cutting (perforations for lighting boxes), and when mixing putty powder, it is recommended to work with a face mask.