Wood Plastic Composite WPC

Wood Plastic Composite (WPC) is an innovative and environmentally friendly material made from a combination of recycled plastic and small wood particles or fibers. Known for its excellent dimensional stability and natural resistance to decay, fungi, and insect attacks, WPC is becoming increasingly popular in the North American market. This unique material stands out due to its low maintenance costs and its environmentally friendly approach of using waste wood and recycled plastic.

Our Expertise

With over 28 years of experience in the production of Wood Plastic Composite, our manufacture is a leader in development and innovation. Through extensive research and laboratory testing, we have created a product that exceeds the performance and expectations of our consumers. We are proud to include WPC in the BennerUSA family of products.

Benefits of WPC

- Environmentally Friendly: Utilizes waste wood and recycled plastic materials.

- Low Maintenance: Requires less upkeep compared to solid wood.

- Durability: Resistant to decay, fungi, and insect attacks.

- Dimensional Stability: Less variability than solid wood, ensuring consistent performance.

Wood Plastic Composite vs Timber

Why choose wood plastic composite products?

Let us show you in a summary table to help explain the key difference between WPC and Timber.

|

Wood Plastic Composite |

Timber |

|

| Humid Stability |

More stable |

Will expand after water absorption |

|

Durability |

Long |

Short |

| Termite Resistance |

Yes |

No |

| UV Resistance |

High |

Low |

| Acid and alkali resistance |

High |

Low |

| Weather resistant |

Yes |

No |

| Painting |

No need |

Yes |

|

Cleaning |

Easy |

Middle |

| Maintenance Cost |

Low cost |

High cost |

Manufacturing of WPC (Wood Plastic Composite)

Our WPC manufacturing process involves combining recycled wood fibers with thermoplastic resins, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or polylactic acid (PLA). The mixture is heated and extruded into the desired shape, then cooled and cut to length. The final product can be planed, sanded, or treated to enhance its appearance and durability before being stored for distribution.

Applications of WPC

The versatility of WPC makes it suitable for a wide range of applications, both indoors and outdoors. Common uses include:

- Outdoor Deck Floors: A popular choice for its durability and low maintenance.

- Railings and Fences: Provides a sturdy and aesthetically pleasing option.

- Landscaping Timbers and Cladding: Ideal for enhancing outdoor spaces.

- Park Benches and Prefab Houses: Combines functionality with sustainability.

- Indoor Furniture and Window/Door Frames: Offers a modern and eco-friendly alternative.

Explore the benefits of Wood Plastic Composite and discover how our innovative products can transform your projects with sustainability and style.

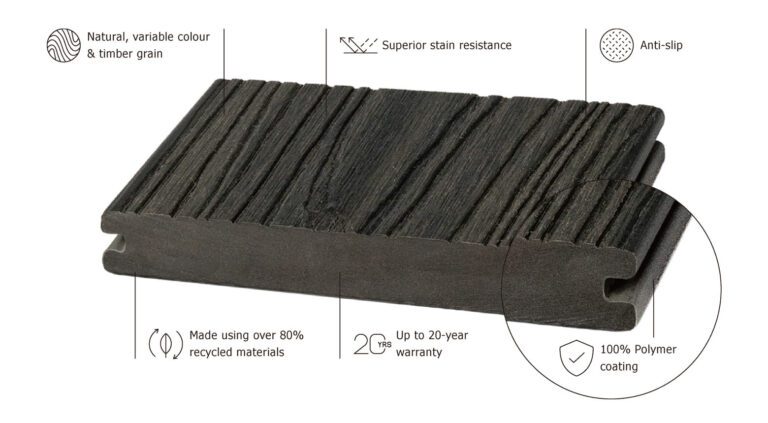

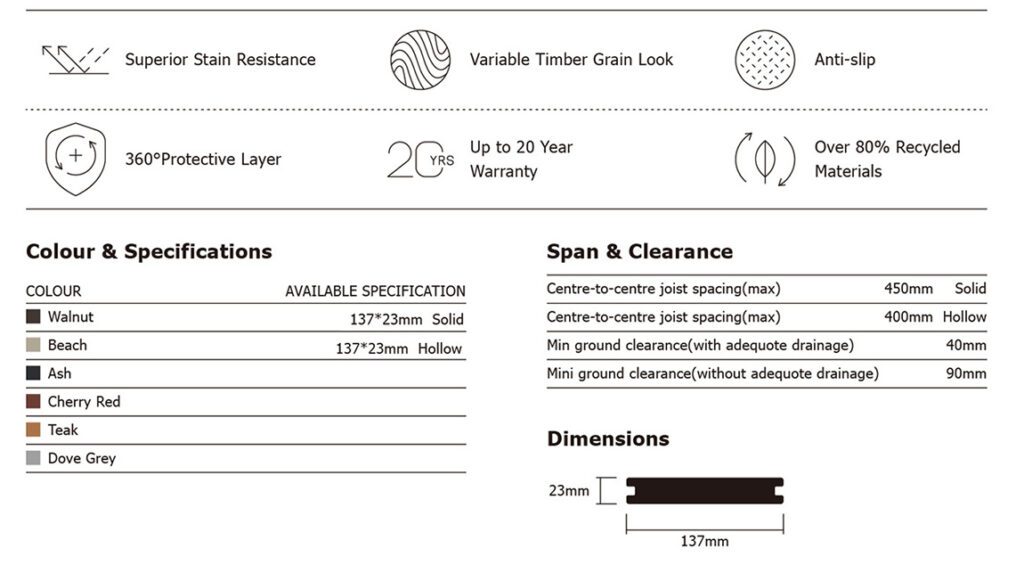

WPC Co-Extrusion Solid Decking

Co-extrusion composite decking is crafted from a wood plastic composite core and an engineering polymer covering that acts as a 360° shield. This covering protects the core from water, UV rays, fungi, staining, and scratching. By using this shield, WPC decking avoids problems like color fading, rotting, cracking, and mold. Additionally, co-extrusion decking offers the advantages of scratch resistance, stain resistance, a longer lifespan, and a wider selection of colors and wood grain patterns. This durable and aesthetically versatile decking option ensures long-lasting performance and minimal maintenance. Perfect for both residential and commercial projects, it enhances outdoor spaces with its reliable functionality and appealing design, making it a superior choice for modern construction needs.

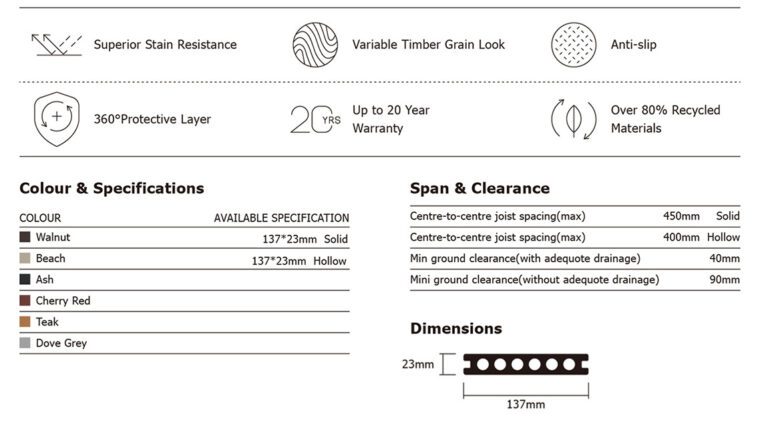

WPC Co-Extrusion Hollow Decking

WPC Co-Extrusion Hollow Decking uses advanced co-extrusion technology, featuring a high-performance, moisture-resistant polymer outer shell that is anti-scratch and easy to clean. This shell protects the inner WPC core from water absorption. The shield and core are extruded simultaneously, eliminating the need for adhesives or harmful chemicals. This environmentally friendly decking offers a natural surface and stable quality, making it increasingly popular for yard applications.

The 360° shield protects against water, UV rays, fungi, staining, and scratching, preventing issues like color fading, rotting, cracking, and mold. Co-extrusion decking is scratch-resistant, stain-resistant, long-lasting, and available in various colors and wood grain patterns, making it a durable and versatile choice for any outdoor space.

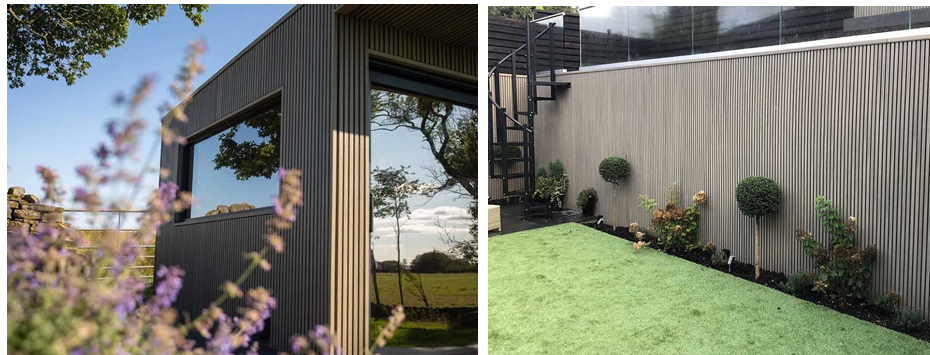

Co-Extrusion Wall Panel:

The co-extrusion wall panel is a product that enhances the aesthetics of a space, generating a positive and welcoming impact to the eye. It is used as decoration for both exterior and interior, and its function is not only to beautify but also to protect. WPC wall panels are more attractive than traditional exterior walls due to their ecological properties and aesthetic appearance. WPC wall panels are made from recycled plastic and wood fibers, come in various colors, and are resistant to water, moisture, and insects. The wall panels do not rot or warp, so maintenance costs are very low, and they can improve thermal, acoustic, and natural light performance.

WPC Wall Panels:

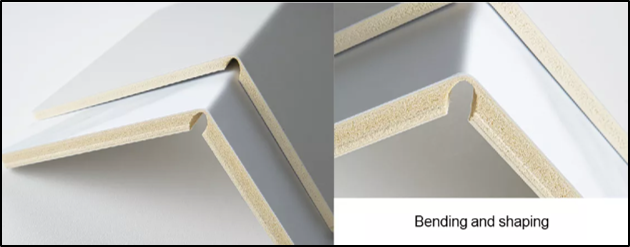

Name: WPC wall panel | Material: Nanofiber powder | Length and width: 1220*2440(mm) 1220*2800(mm) 1220*Custom length(mm) | Thickness: 5mm&8mm | Density: 700kg/m³ | Environmental protection grade: ENF | Fire rating: B1 | Performance: waterproof & bendable

SPC Background Walls:

Material / Cross-section: SPC+UV | Width: 1120 mm | Length: 2800 mm | Thickness: 6 mm | Surface Tech: Laser Inking